whatsapp:+86 13622680352

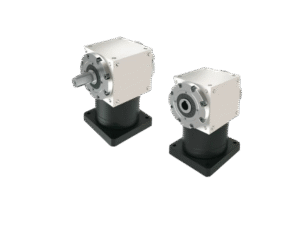

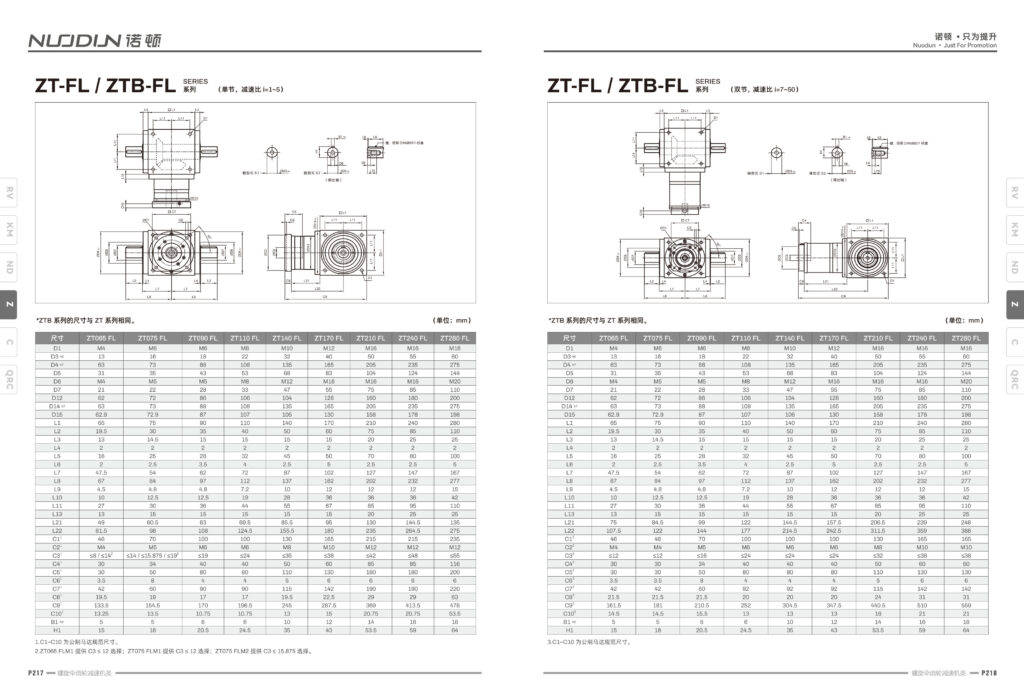

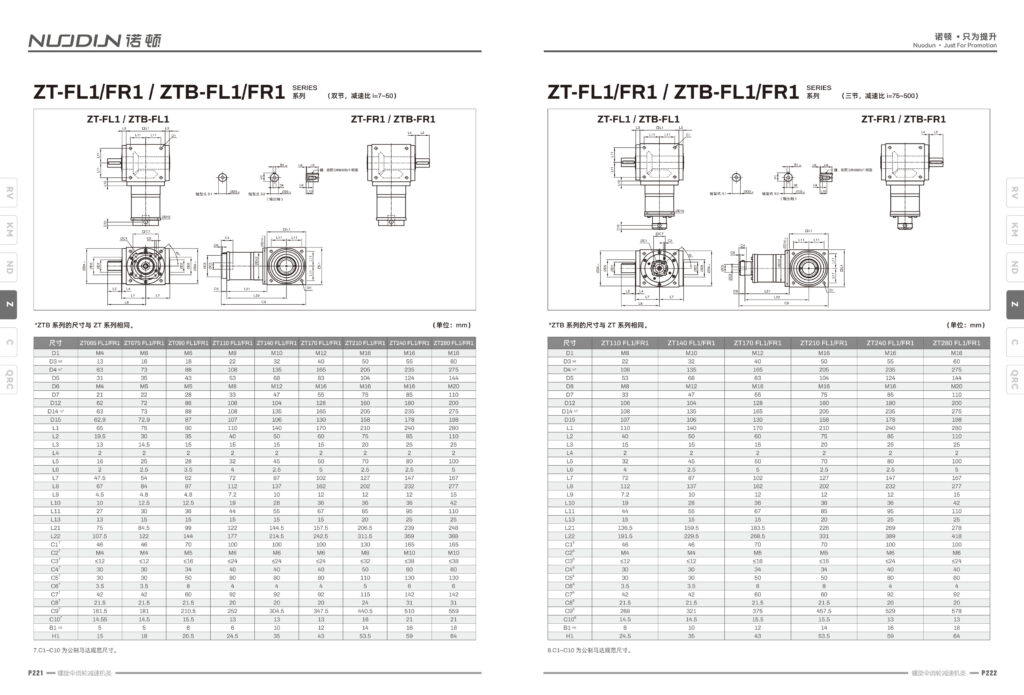

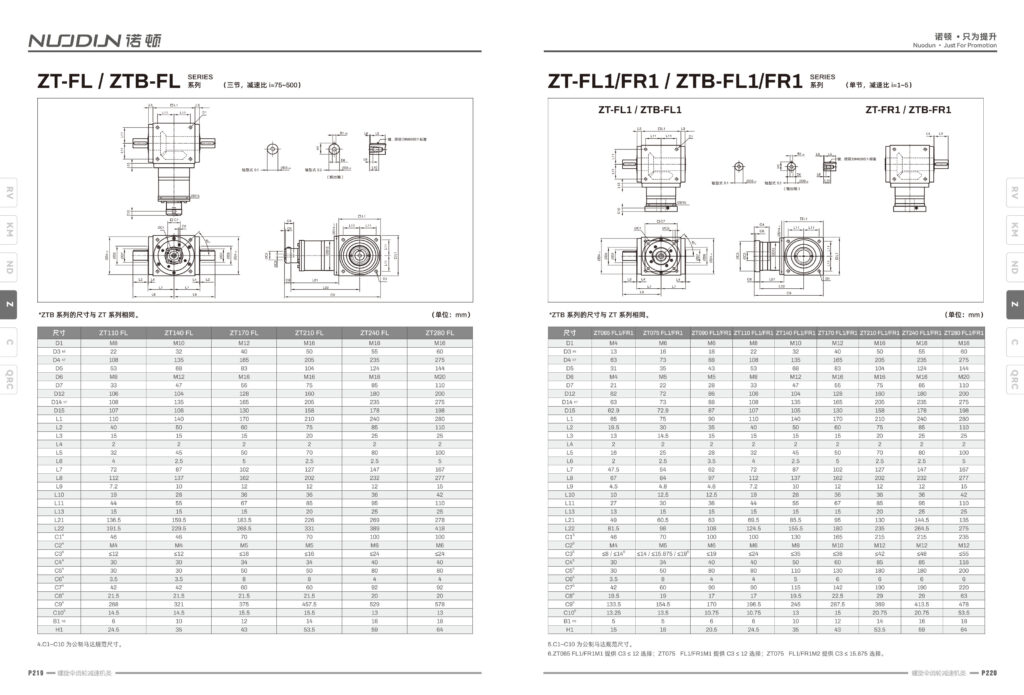

ZT / ZTB Spiral Bevel Gear Reducer

ZT / ZTB Spiral Bevel Gear Reducer

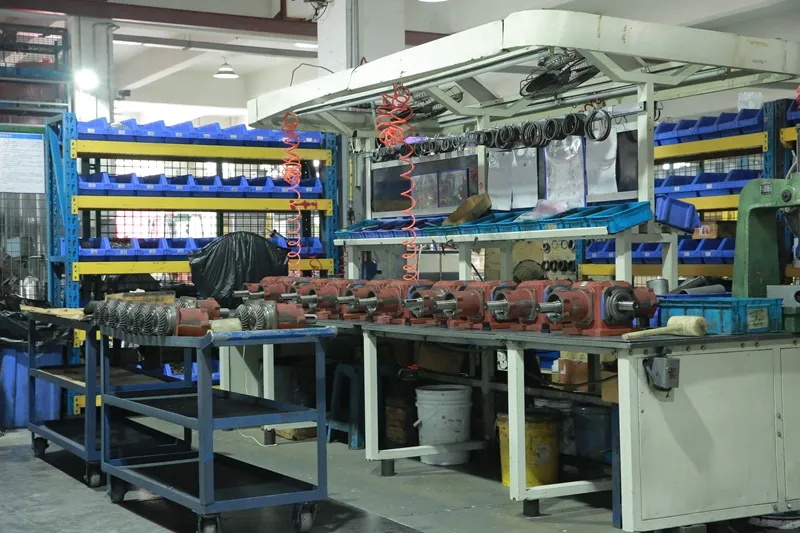

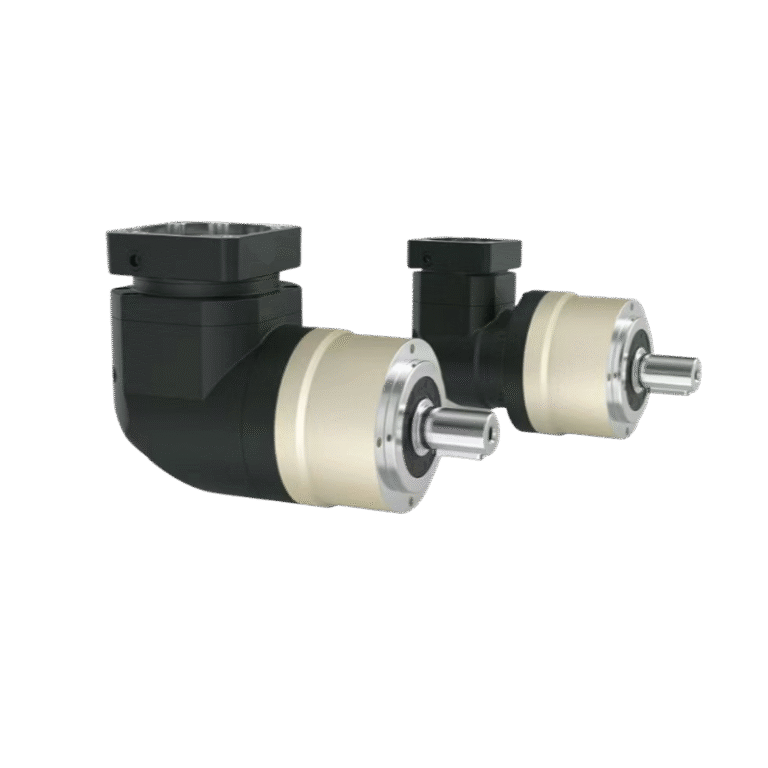

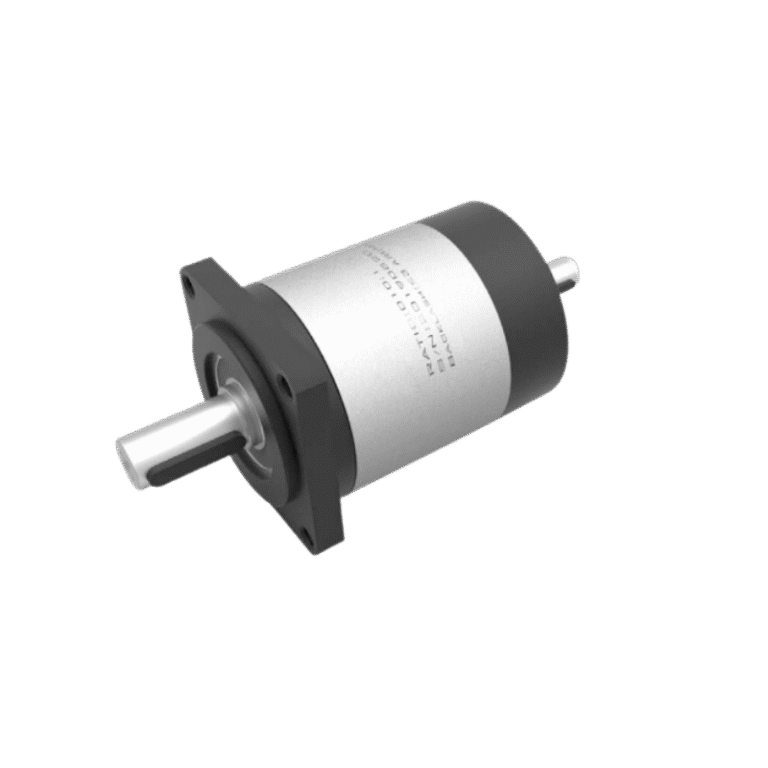

ZT / ZTB Series Spiral Bevel Gear Reducer is engineered for applications requiring smooth right-angle power transmission, high torque density, and long-term operational reliability. Built with precision-machined spiral bevel gears, this series ensures stable rotation, low vibration, and efficient torque output under both continuous and dynamic loads.

- Different housing material design

- Aluminum alloy – ZT

- Cast iron – ZTB

- Various output shaft options

- High efficiency

- Long service life

- Low backlash

- Maintenance-free

- Flexible installation dimensions

Features

Description

ZT / ZTB Series Spiral Bevel Gear Reducer is engineered for applications requiring smooth right-angle power transmission, high torque density, and long-term operational reliability. Built with precision-machined spiral bevel gears, this series ensures stable rotation, low vibration, and efficient torque output under both continuous and dynamic loads.

Two housing options allow optimized performance for different industrial environments:

ZT (Aluminum Alloy) for lightweight, corrosion-resistant, high-heat-dissipation applications;

ZTB (Cast Iron) for heavy-duty, high-rigidity installations operating under demanding mechanical loads.

The series offers multiple output shaft configurations, low backlash, maintenance-free lubrication, and flexible installation interfaces, making it ideal for modern automation systems requiring durable and precise right-angle transmission units.

Features

⦁ Spiral bevel gear design for smooth, high-efficiency right-angle transmission

⦁ Available in lightweight aluminum (ZT) or heavy-duty cast iron (ZTB) housings

⦁ Multiple output shaft configurations to match diverse application needs

⦁ High torque capacity with stable output under continuous load

⦁ High transmission efficiency with reduced energy loss

⦁ Long service life with robust internal gearing and bearings

⦁ Low backlash for precision motion control

⦁ Maintenance-free lubrication for reduced downtime

⦁ Flexible mounting dimensions for easy integration

ZPER Series Performance Table

Application

The ZT / ZTB Series Spiral Bevel Gear Reducers are suitable for a wide range of industrial applications, including:

• Automation equipment requiring right-angle servo or motor positioning

• Packaging machinery, conveyors, sorting machines, and material handling lines

• CNC equipment, precision motion platforms, and robotic arms

• Food processing, pharmaceutical, and chemical machinery (aluminum housing recommended)

• Heavy-load industries such as metallurgy, mining, and steel processing (cast-iron housing recommended)

• Textile, woodworking, and electronics manufacturing systems

• Any system requiring compact, high-rigidity, right-angle power transmission

FAQs

Yes. NUODUN’s core competitiveness lies in the synergistic advantage of “customization + system integration.” We support structural customization, torque customization, input flange customization, mounting interface customization, stroke customization and more for products such as planetary gearboxes, screw jacks, electric cylinders, and gearboxes. The typical lead time for standard non-standard customization is 7–20 days, while more complex engineered projects are usually delivered within 3–6 weeks.

Our engineering strength comes from long-term R&D investment, CAE simulation, lifetime calculation databases, modular design frameworks, and a mature testing/verification system. This ensures that every customized solution is not only manufacturable, but also reliable under real-world loads — balancing precision, durability, and cost efficiency.

Our products are widely used in photovoltaic manufacturing, semiconductor equipment, automotive production, metallurgy, logistics, medical devices, aerospace, stage automation, and industrial automation — especially where precision positioning, heavy loads, or long service life are required.

All products undergo type testing, torque testing, vibration testing, life testing, noise measurement, and precision inspection. Core components such as gears, screws, and bearings are produced using advanced machining, grinding, heat treatment, and automated assembly processes.

Yes. We offer remote technical support, installation guidance, troubleshooting, selection assistance, and long-term spare parts support for OEM/ODM partners.