whatsapp:+86 13622680352

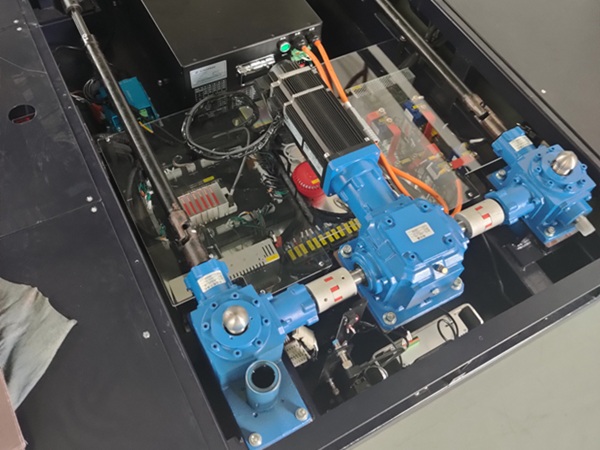

Gear Drives & Actuators in Aircraft Dock Maintenance Platforms

Aircraft dock maintenance platforms require precise lifting, smooth motion control, and absolute reliability to ensure safe access to the fuselage, tail, and engine areas during inspection and servicing. These platforms must operate flawlessly in outdoor environments, often exposed to extreme temperatures, high humidity, and continuous mechanical load.

NUODUN supplied a customized system of high-reliability gear reducers and electromechanical actuators engineered specifically for aviation ground support equipment (GSE), including maintenance docks and engine test stands.

Application

The platform shown integrates multiple NUODUN worm-gear reducers and screw-jack actuators to control vertical lifting, leveling, and platform positioning. These motion units provide synchronized adjustment of multi-level access structures, ensuring stable alignment with the aircraft tail and fuselage.

Key Functions

- Precise height and position adjustment

Ensures safe and accurate alignment of multi-level maintenance platforms around the aircraft structure. - High load-bearing capability

Designed to support the full weight of steel platform structures and dynamic loads from maintenance personnel and equipment. - Reliable operation in extreme temperature environments

Specialized lubrication and materials provide stable performance from –50°C to +120°C, suitable for harsh outdoor airport conditions. - Smooth synchronized lifting

Multi-actuator systems maintain platform levelness and structural stability during movement. - Low maintenance, long service life

Hardened gear surfaces, sealed housings, and corrosion-resistant coatings ensure durability even in coastal or high-humidity environments.

Why NUODUN Was Selected

- Aerospace-level reliability for GSE and maintenance applications

- Extreme-temperature resistance suitable for diverse climates and airport operations

- Custom engineering capabilities to match platform structure, loading, and safety requirements

- Proven performance in heavy lifting and multi-axis positioning systems

- Stable operation under continuous duty cycles typical of MRO (Maintenance, Repair & Overhaul) environments

Customer Benefits

- Enhanced work safety with precise and stable platform movements

- Reduced downtime through robust mechanical design and low maintenance needs

- Improved alignment accuracy for tail and fuselage maintenance tasks

- Reliable operation in extreme climates, from winter frost to high-temperature apron conditions

- Longer equipment lifespan and lower total cost of ownership