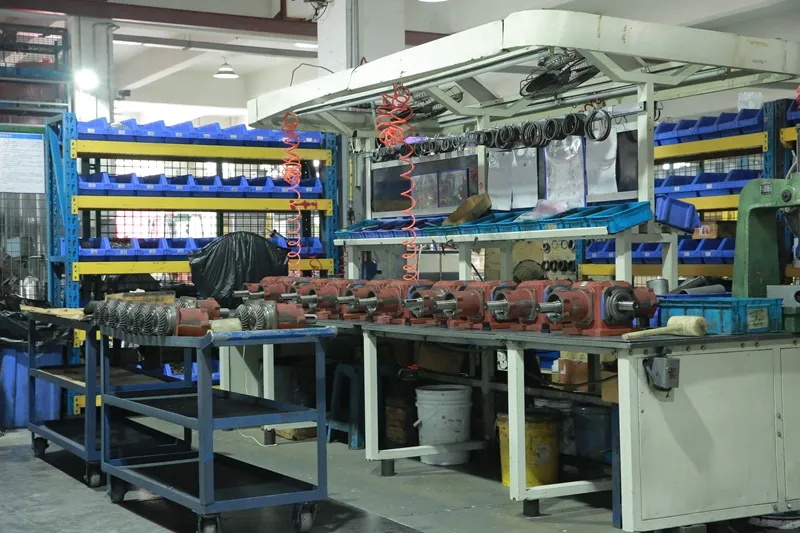

whatsapp:+86 13622680352

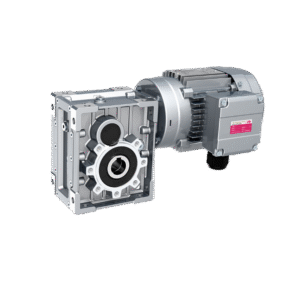

KM Helical Hypoid Gear Reducer

KM Helical Hypoid Gear Reducer

Features

-

High-Torque Hypoid Gear Transmission

Delivers superior efficiency and strong output torque for demanding industrial applications. -

Energy-Efficient & Smooth Operation

Reduced power loss compared with worm gears, ensuring quieter and more stable performance. -

Lightweight, Corrosion-Resistant Aluminum Housing

Durable die-cast construction with excellent heat dissipation and long service life. -

Low Noise & Stable Running

Minimal vibration and reliable continuous operation even in harsh environments. -

Compact Design with Flexible Installation

Small footprint and multiple mounting orientations for easy integration. -

Modular Configurations & NMRV Compatibility

Supports multi-stage gearing and matches NMRV mounting dimensions for versatile industrial use.

Description

KM Series Helical Hypoid Gear Units are the latest generation of compact, high-efficiency gear reducers developed by NUODUN. Designed with advanced hypoid gear technology, the KM series delivers high torque density, smooth transmission, long service life, and superior energy efficiency compared to conventional worm gear reducers.

Featuring lightweight aluminum housing, high-strength alloy steel gears, multiple installation options, and compatibility with NMRV worm gear mounting dimensions, the KM series is ideal for a wide range of automation and power transmission applications.

Features

1. Hypoid Gear Drive with High Torque Output

Delivers large output torque with high transmission efficiency, making it suitable for demanding industrial applications.

2. Energy Saving & High Efficiency

Compared with worm gear units, hypoid gears reduce energy loss and enable smoother, quieter operation.

3. Lightweight & Corrosion-Free Housing

Manufactured from high-quality die-cast aluminum alloy, providing low weight, excellent thermal dissipation, and rust-free service life.

4. Smooth Operation & Low Noise

Stable running with minimal vibration, suitable for long-term continuous operation in harsh environments.

5. Compact Structure & Attractive Appearance

Small volume, easy installation, aesthetically clean exterior, and long operational life.

6. Wide Installation Flexibility

Supports all-round mounting positions (B3, B6, B7, etc.) and modular configurations.

7. NMRV Compatibility

Mounting dimensions compatible with NMRV worm gear reducers (except partial dimensions of NMRV050 vs. KM28).

8. Modular & Multi-Structure Options

Multiple gear stages (2-stage & 3-stage) and ratios support diverse industrial applications.

Materials & Construction

Housing

- Die-cast aluminum alloy (Frame size 28–58)

- Shot-blasted, degreased, and coated with RAL5010 blue paint

- Custom colors available upon request

Gears

- Material: 20CrMnTiH1 alloy steel

- Heat treatment: carbonizing & quenching

- Surface hardness: 56–62 HRC

- Carburized layer thickness: 0.3–0.5 mm after precision grinding

Technical Specifications

KM28 Series (160 Nm)

3-Stage

| Model | Nominal i | Actual i | Output Speed n₂ (r/min) | Max Torque (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM28C | 300 | 294.05 | 4.8 | 130 | 4100 |

| KM28C | 250 | 244.29 | 5.8 | 130 | 4100 |

| KM28C | 200 | 200.44 | 7.0 | 130 | 4100 |

| KM28C | 150 | 146.67 | 9.6 | 160 | 4000 |

| KM28C | 125 | 120.34 | 12 | 160 | 3770 |

| KM28C | 100 | 99.41 | 14 | 160 | 3560 |

| KM28C | 90 | 91.48 | 15.5 | 160 | 3330 |

| KM28C | 75 | 74.62 | 19 | 160 | 3220 |

2-Stage

| Model | Nominal i | Actual i | Output Speed | Max Torque | Fr |

|---|---|---|---|---|---|

| KM28B | 60 | 58.81 | 24 | 130 | 2960 |

| KM28B | 50 | 48.86 | 29 | 130 | 2790 |

| KM28B | 40 | 40.09 | 35 | 130 | 2610 |

| KM28B | 30 | 30.54 | 48 | 160 | 2350 |

| KM28B | 25 | 24.86 | 59 | 160 | 2200 |

| KM28B | 20 | 19.88 | 70 | 160 | 2080 |

| KM28B | 15 | 14.92 | 93 | 160 | 1880 |

| KM28B | 12.5 | 12.47 | 113 | 160 | 1770 |

| KM28B | 10 | 10.30 | 134 | 160 | 1670 |

| KM28B | 7.5 | 7.73 | 182 | 160 | 1510 |

KM38 Series (200 Nm)

3-Stage

| Model | Nominal i | Actual i | n₂ (r/min) | M2max (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM38C | 300 | 302.5 | 4.7 | 160 | 4800 |

| KM38C | 250 | 243.57 | 5.8 | 160 | 4800 |

| KM38C | 200 | 196.43 | 7.2 | 160 | 4800 |

| KM38C | 150 | 151.56 | 9.3 | 180 | 4650 |

| KM38C | 125 | 122.22 | 12 | 180 | 4330 |

| KM38C | 100 | 101.27 | 14 | 180 | 4070 |

| KM38C | 90 | 91.25 | 16 | 180 | 3920 |

| KM38C | 75 | 73.33 | 20 | 180 | 3650 |

2-Stage

| Model | Nominal i | Actual i | n₂ (r/min) | M2max (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM38B | 60 | 60.50 | 24 | 160 | 3430 |

| KM38B | 50 | 48.71 | 29 | 160 | 3190 |

| KM38B | 40 | 39.29 | 36 | 160 | 2970 |

| KM38B | 30 | 30.31 | 47 | 180 | 2720 |

| KM38B | 25 | 24.44 | 58 | 180 | 2530 |

| KM38B | 20 | 20.25 | 70 | 180 | 2380 |

| KM38B | 15 | 15.71 | 96 | 180 | 2130 |

| KM38B | 12.5 | 12.67 | 111 | 180 | 2030 |

| KM38B | 10 | 10.50 | 134 | 180 | 1910 |

| KM38B | 7.5 | 7.60 | 185 | 180 | 1710 |

KM48 Series (350 Nm)

3-Stage

| Model | Nominal i | Actual i | n₂ (r/min) | M2max (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM48C | 300 | 297.21 | 4.7 | 350 | 6500 |

| KM48C | 250 | 240.89 | 5.8 | 350 | 6500 |

| KM48C | 200 | 200.66 | 7.0 | 350 | 6500 |

| KM48C | 150 | 151.20 | 9.3 | 350 | 6360 |

| KM48C | 125 | 121.02 | 11.6 | 300 | 5980 |

| KM48C | 100 | 100.81 | 14 | 240 | 5520 |

| KM48C | 75 | 79.41 | 17.7 | 200 | 5040 |

2-Stage

| Model | Nominal i | Actual i | n₂ (r/min) | M2max (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM48B | 60 | 59.44 | 27.8 | 350 | 4660 |

| KM48B | 50 | 48.18 | 29 | 350 | 4340 |

| KM48B | 40 | 40.13 | 34.9 | 300 | 4080 |

| KM48B | 30 | 29.86 | 46.9 | 350 | 3720 |

| KM48B | 25 | 24.20 | 57.9 | 300 | 3500 |

| KM48B | 20 | 20.16 | 69.4 | 240 | 3230 |

| KM48B | 15 | 15.58 | 88.2 | 200 | 2950 |

| KM48B | 12.5 | 12.49 | 112 | 300 | 2770 |

| KM48B | 10 | 9.84 | 142.3 | 240 | 2550 |

| KM48B | 7.5 | 7.48 | 187.2 | 200 | 2330 |

KM58 Series (500 Nm)

3-Stage

| Model | Nominal i | Actual i | n₂ (r/min) | M2max (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM58C | 300 | 295.18 | 4.7 | 500 | 8300 |

| KM58C | 250 | 240.89 | 5.8 | 500 | 8300 |

| KM58C | 200 | 200.66 | 7.0 | 480 | 8300 |

| KM58C | 150 | 151.20 | 9.3 | 500 | 8050 |

| KM58C | 125 | 125.95 | 11.1 | 480 | 7580 |

| KM58C | 100 | 99.22 | 14.1 | 380 | 7000 |

| KM58C | 75 | 75.45 | 18.5 | 300 | 6390 |

2-Stage

| Model | Nominal i | Actual i | n₂ (r/min) | M2max (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM58B | 60 | 59.04 | 23.7 | 500 | 5890 |

| KM58B | 50 | 48.18 | 29 | 500 | 5500 |

| KM58B | 40 | 40.13 | 34.9 | 480 | 5170 |

| KM58B | 30 | 30.24 | 46.3 | 500 | 4710 |

| KM58B | 25 | 25.19 | 55.6 | 480 | 4430 |

| KM58B | 20 | 19.84 | 70.56 | 380 | 4090 |

| KM58B | 15 | 14.99 | 93.3 | 300 | 3730 |

| KM58B | 12.5 | 12.49 | 112 | 480 | 3510 |

| KM58B | 10 | 9.84 | 142.3 | 400 | 3240 |

| KM58B | 7.5 | 7.48 | 187.2 | 300 | 2950 |

KM68 Series (750 Nm)

3-Stage

| Model | Nominal i | Actual i | n₂ (r/min) | M2max (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM68C | 300 | 298.57 | 4.7 | 750 | 10000 |

| KM68C | 250 | 250.10 | 5.6 | 750 | 10000 |

| KM68C | 200 | 195.43 | 7.2 | 750 | 9740 |

| KM68C | 150 | 156.07 | 9 | 750 | 9040 |

| KM68C | 125 | 122.67 | 11.4 | 750 | 8340 |

| KM68C | 100 | 97.96 | 14.3 | 650 | 7740 |

| KM68C | 75 | 75.51 | 18.5 | 520 | 7090 |

2-Stage

| Model | Nominal i | Actual i | n₂ (r/min) | M2max (Nm) | Fr (N) |

|---|---|---|---|---|---|

| KM68B | 60 | 59.71 | 23 | 750 | 6560 |

| KM68B | 50 | 50.02 | 28 | 750 | 6180 |

| KM68B | 40 | 39.09 | 36 | 750 | 5690 |

| KM68B | 30 | 31.21 | 45 | 750 | 5280 |

| KM68B | 25 | 24.53 | 57 | 750 | 4870 |

| KM68B | 20 | 19.59 | 71 | 650 | 4520 |

| KM68B | 15 | 15.10 | 93 | 520 | 4150 |

| KM68B | 12.5 | 12.16 | 115 | 520 | 3860 |

| KM68B | 10 | 9.71 | 144 | 650 | 3580 |

| KM68B | 7.5 | 7.48 | 187 | 520 | 3280 |

Application

KM series hypoid gear units are designed for low-speed, high-torque, compact transmission systems, widely used in:

Light Load

- Screw conveyors

- Fans & blowers

- Packaging lines

- Light-duty elevators

- Washing equipment

- Filters

- Control drives

Medium Load

- Hoists & lifts

- Woodworking feeders

- Winches

- Sliding gates

- Scraper conveyors

- Mixing equipment

- Calendering machines

- Gear pumps

Heavy Load

- Centrifuges

- Crushers & mills

- Press machines

- Rotary tables

- Excavation & mining machinery

- Heavy-duty winches & cranes

Service Factor (fs) Selection Guide

Proper service factor ensures gearbox life & reliability.

Determine fs Based On:

- Daily operating hours

- Start/stop frequency

- Load type (light/medium/heavy)

- Inertia & acceleration factor

Example:

- Inertia acceleration factor = 2.5

- Operation = 14 hours/day

- Start-stop = 200 times/hour

From the service chart:

fs = 1.48

Therefore, the selected gearbox must have

fs (catalog) ≥ 1.48

Lubrication & Maintenance

1. First Oil Change

After 300 hours (running-in period)

2. Regular Inspection

- Check oil condition & level every 3000 hours or every 6 months

- Inspect oil seals and replace if leaking

- For IEC input types, check the elastic coupling

3. Periodic Replacement

- Replace mineral oil at least every 3 years

- Replace output shaft oil seals based on actual working conditions

4. Important Notice

If a failure occurs, do not disassemble — contact NUODUN support with:

- Model

- Serial number

- Operating hours

- Host machine type

- Failure description

The NUODUN KM Series Helical Hypoid Gear Units offer:

- High torque, compact structure

- High efficiency & low noise

- Aluminum lightweight housing

- Hypoid gear technology

- Wide ratio range

- NMRV-compatible mounting

- Long life & easy maintenance

FAQs

Yes. NUODUN’s core competitiveness lies in the synergistic advantage of “customization + system integration.” We support structural customization, torque customization, input flange customization, mounting interface customization, stroke customization and more for products such as planetary gearboxes, screw jacks, electric cylinders, and gearboxes. The typical lead time for standard non-standard customization is 7–20 days, while more complex engineered projects are usually delivered within 3–6 weeks.

Our engineering strength comes from long-term R&D investment, CAE simulation, lifetime calculation databases, modular design frameworks, and a mature testing/verification system. This ensures that every customized solution is not only manufacturable, but also reliable under real-world loads — balancing precision, durability, and cost efficiency.

Our products are widely used in photovoltaic manufacturing, semiconductor equipment, automotive production, metallurgy, logistics, medical devices, aerospace, stage automation, and industrial automation — especially where precision positioning, heavy loads, or long service life are required.

All products undergo type testing, torque testing, vibration testing, life testing, noise measurement, and precision inspection. Core components such as gears, screws, and bearings are produced using advanced machining, grinding, heat treatment, and automated assembly processes.

Yes. We offer remote technical support, installation guidance, troubleshooting, selection assistance, and long-term spare parts support for OEM/ODM partners.