whatsapp:+86 13622680352

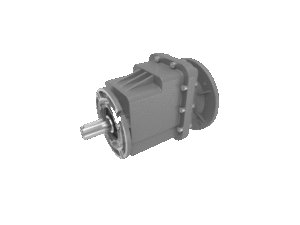

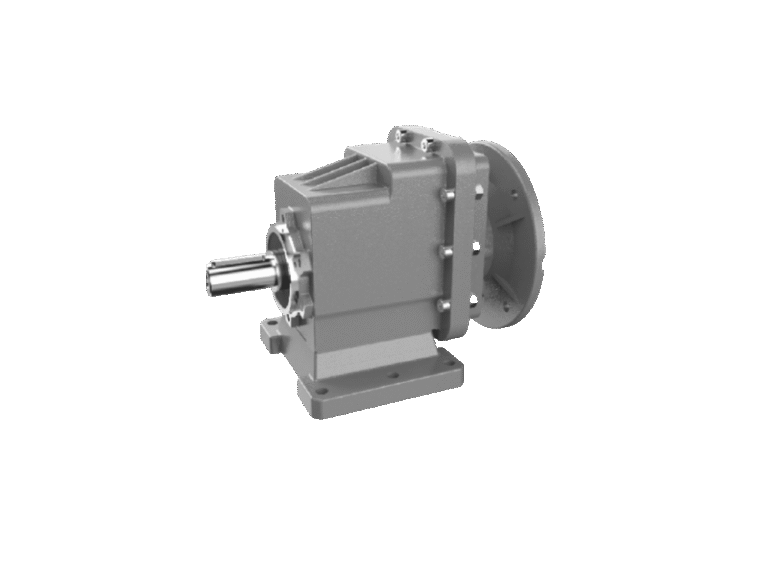

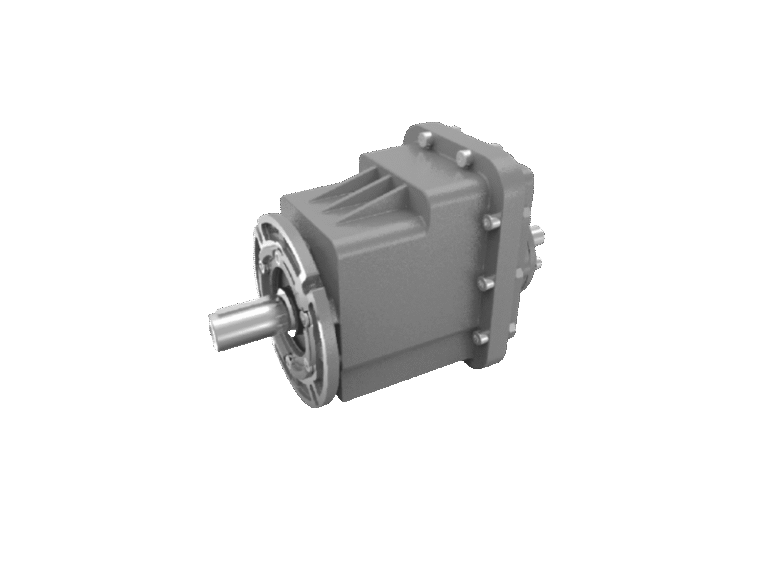

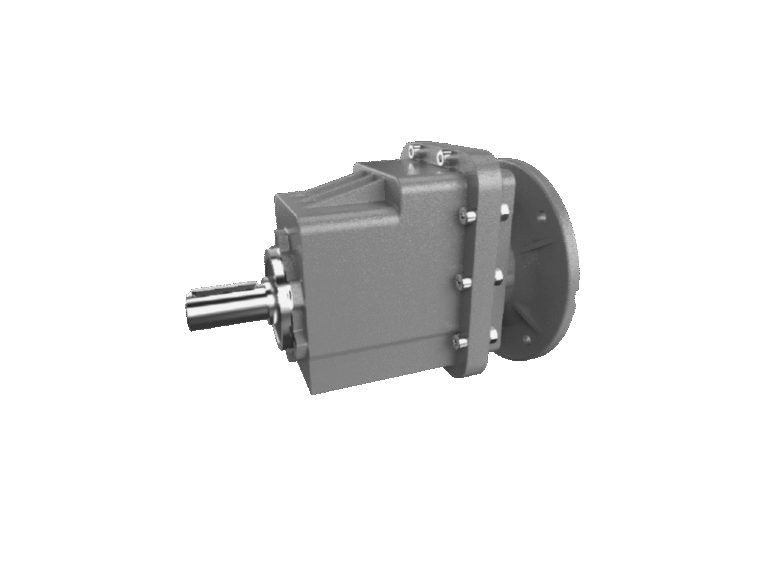

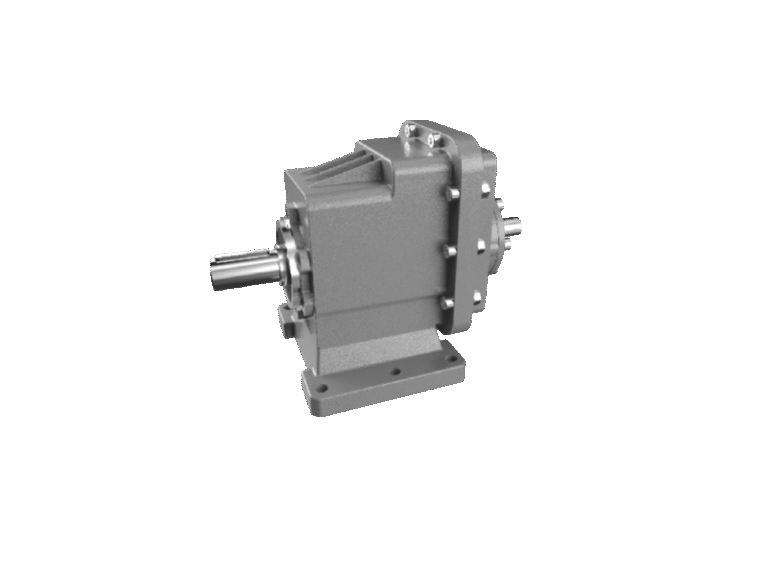

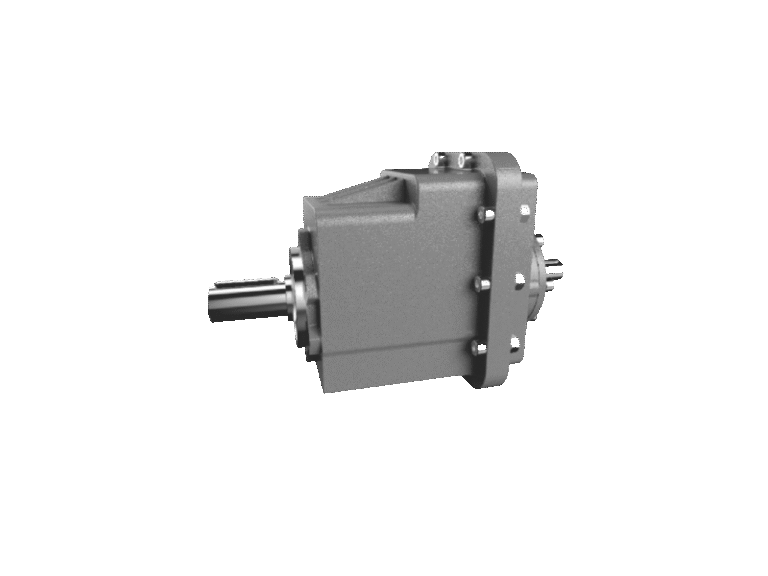

QRCFP (IEC) Flange-Mounted Helical Gear Unit

QRCFP (IEC) Flange-Mounted Helical Gear Unit

Features

- Standard IEC flange-mounted design for seamless motor integration

- High structural rigidity ensures accurate alignment and stable operation

- Capable of delivering high torque output up to 500 Nm

- Precision-ground helical gears minimize vibration and improve efficiency

- Low-noise performance suitable for continuous industrial applications

- Compatible with a wide range of IEC motors, including servo motor options

Description

ORCFP (IEC) series is a flange-mounted helical gear reducer designed with an IEC-standard motor interface, enabling easy and direct mounting of IEC motors without additional adapters. Based on the QRC modular helical gear platform, the ORCFP model features precision-machined helical gears, hardened & carburized gear surfaces, and a robust housing to ensure stable torque transmission and long service life.

The compact flange-mounted design makes the ORCFP series ideal for machinery with limited installation space or where direct motor–gearbox integration is required. Its high efficiency, low noise, and versatile configuration options make it suitable for textile machinery, food processing lines, ceramics equipment, logistics conveyors, packaging machines, plastics processing, and general automation systems.

Features

- Standard flange-mounted design

- Excellent rigidity and alignment accuracy

- High torque output up to 500 Nm

- Precision-ground helical gears reduce vibration

- Compatible with IEC standard motors including servo options

Selection Factors

- Flange matching dimensions and bolt pattern

- Direction of load (radial/axial)

- Working hours vs starting frequency (fs)

- Required torque and ratio

Technical Parameters

| Item | Specification |

|---|---|

| Power Range | 0.12 – 4 kW |

| Reduction Ratio | 3.66 – 54 |

| Max Output Torque | 120 – 500 Nm |

| Mounting Type | IEC flange-mounted (FP type) |

| Motor Connection | IEC-standard B5/B14 motor flange options |

| Gear Type | Helical, carburized & hardened tooth surfaces |

| Housing Material | Aluminum alloy (small sizes), cast iron optional |

| Input Method | Direct IEC motor connection |

| Output Type | Solid shaft (various diameters depending on size) |

| Installation Positions | All mounting positions supported |

| Lubrication | Oil lubrication (per frame size) |

| Cooling Method | Natural convection |

| Noise Level | Low-noise, smooth operation |

| Typical Applications | Textile, food, ceramics, packaging, logistics, plastics, automation |

Application Scenarios

- Food processing lines

- Automated packaging & sealing equipment

- Plastic extruder auxiliary systems

- General-purpose mechanical transmission

FAQs

Yes. NUODUN’s core competitiveness lies in the synergistic advantage of “customization + system integration.” We support structural customization, torque customization, input flange customization, mounting interface customization, stroke customization and more for products such as planetary gearboxes, screw jacks, electric cylinders, and gearboxes. The typical lead time for standard non-standard customization is 7–20 days, while more complex engineered projects are usually delivered within 3–6 weeks.

Our engineering strength comes from long-term R&D investment, CAE simulation, lifetime calculation databases, modular design frameworks, and a mature testing/verification system. This ensures that every customized solution is not only manufacturable, but also reliable under real-world loads — balancing precision, durability, and cost efficiency.

Our products are widely used in photovoltaic manufacturing, semiconductor equipment, automotive production, metallurgy, logistics, medical devices, aerospace, stage automation, and industrial automation — especially where precision positioning, heavy loads, or long service life are required.

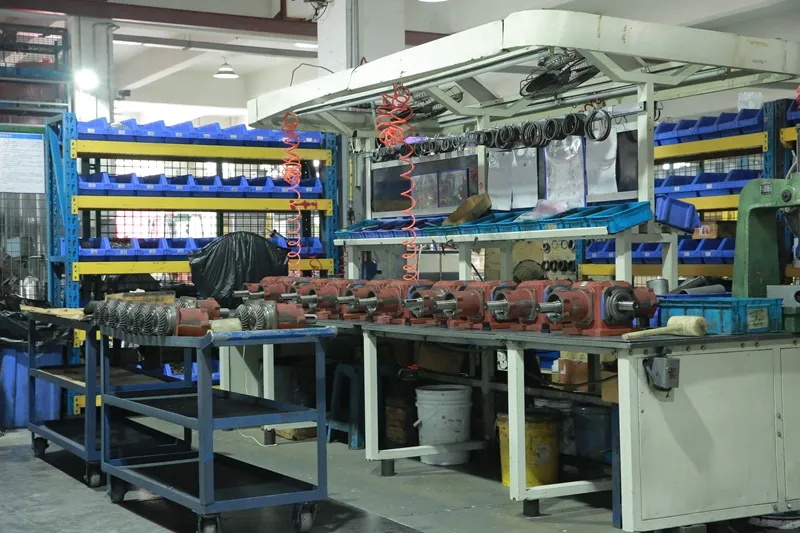

All products undergo type testing, torque testing, vibration testing, life testing, noise measurement, and precision inspection. Core components such as gears, screws, and bearings are produced using advanced machining, grinding, heat treatment, and automated assembly processes.

Yes. We offer remote technical support, installation guidance, troubleshooting, selection assistance, and long-term spare parts support for OEM/ODM partners.