whatsapp:+86 13622680352

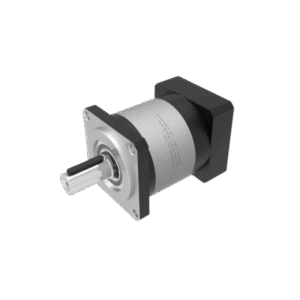

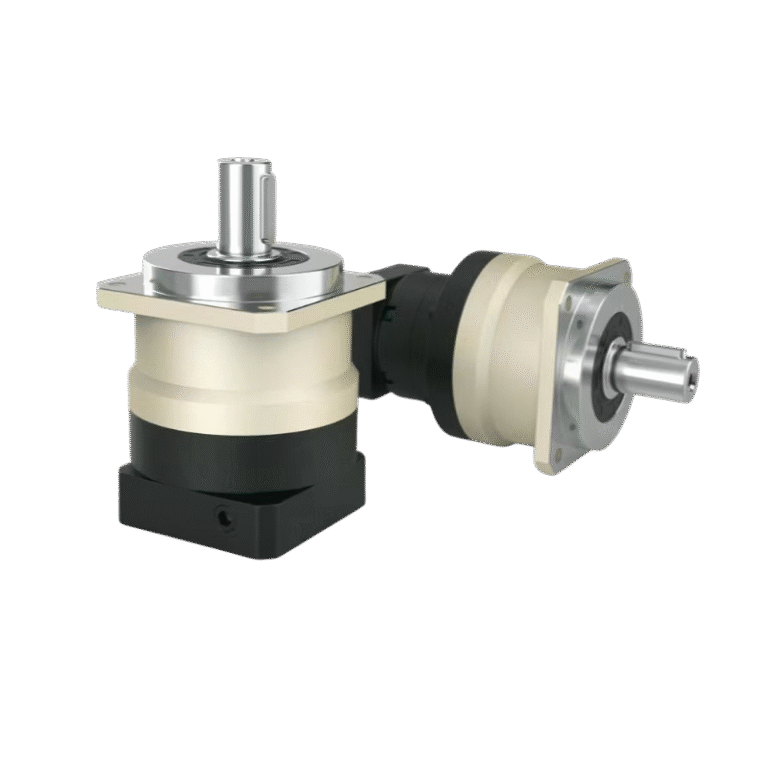

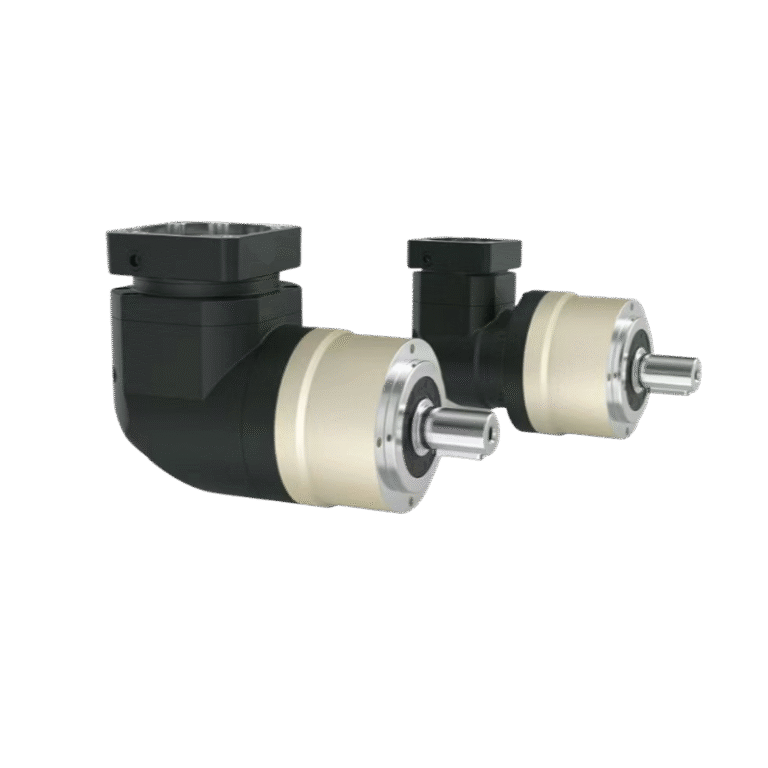

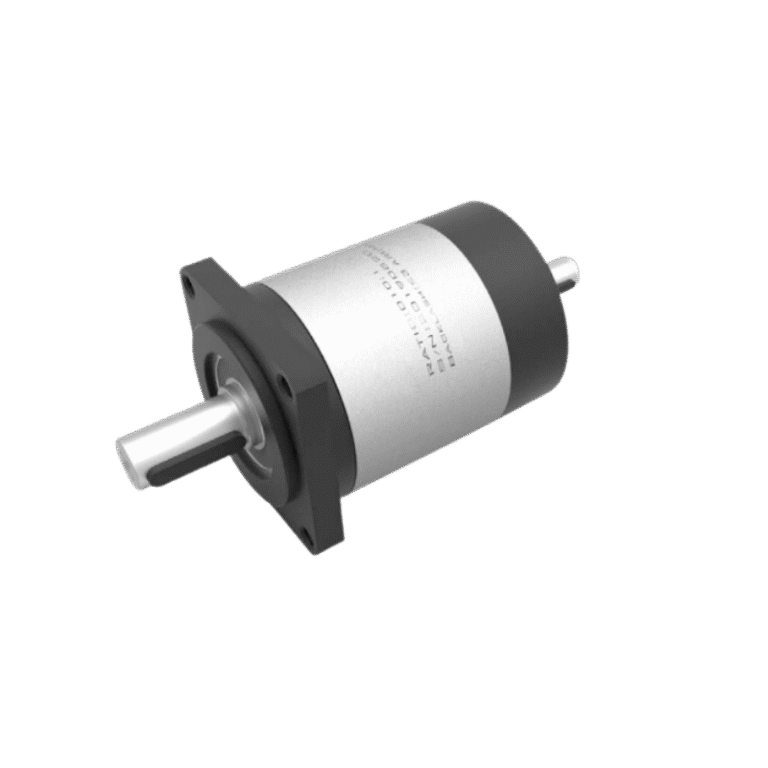

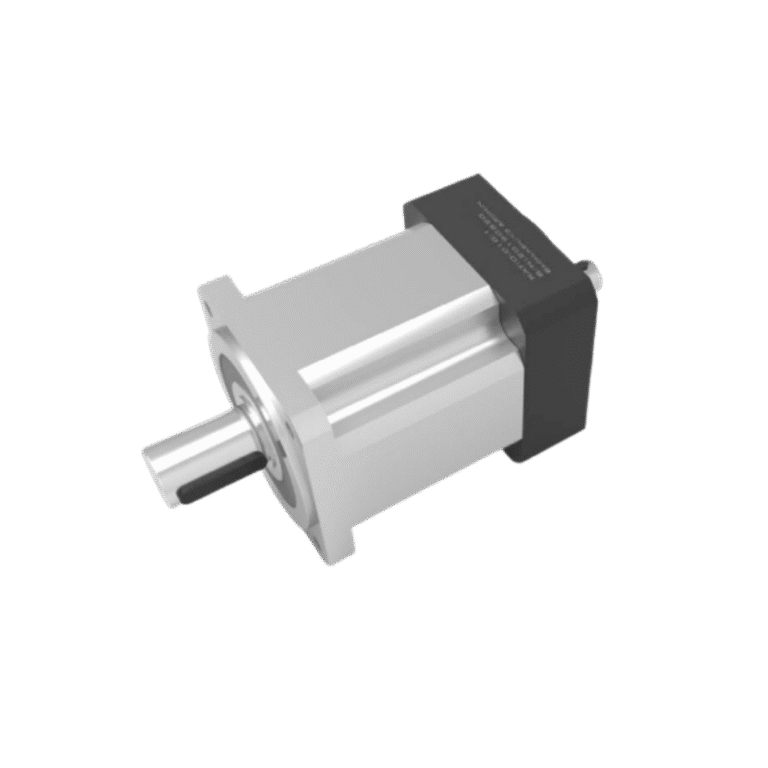

ZE Straight Teeth Planetary Gear Reducer

ZE Straight Teeth Planetary Gear Reducer

Features

Description

NUODUN ZE Series Straight Teeth Planetary Gear Reducer is a high-precision gearbox engineered for stable, efficient, and reliable performance in modern automation and servo motion systems. Utilizing a straight-tooth planetary design, the ZE series offers excellent transmission accuracy, high rigidity, and strong torque capability while maintaining a compact form factor.

Compatible with various servo motor specifications, the ZE series features customizable motor input flanges and universal mounting options, ensuring seamless integration into different machine layouts. Lifetime lubrication ensures long-term maintenance-free operation, allowing the reducer to perform consistently under continuous dynamic loads.

Features

- For any mounting position

- Individual adaptation of the input flange to the motor

- Lifetime lubrication for maintenance-free operation

- Equidirectional rotation

- Wide range of output shaft designs

- Precise gearing

ZE Series Performance Table

(Recreated in English according to the uploaded catalog data)

Rated Output Torque T2N (Nm)

| Ratio | ZE060 | ZE080 | ZE120 | ZE160 |

|---|---|---|---|---|

| 1 Stage | ||||

| 3 | 20 | 50 | 140 | 310 |

| 4 | 18 | 50 | 240 | 605 |

| 5 | 35 | 90 | 210 | 535 |

| 7 | 25 | 75 | 160 | 420 |

| 9 | 20 | 55 | 140 | 360 |

| 10 | 18 | 50 | 90 | 330 |

| 2 Stage | ||||

| 12 | 25 | 75 | 140 | 340 |

| 16 | 20 | 55 | 110 | 300 |

| 20 | 20 | 45 | 100 | 280 |

| 25 | 15 | 40 | 85 | 260 |

| 28 | 15 | 40 | 80 | 240 |

| 32 | 12 | 35 | 70 | 220 |

| 40 | 12 | 30 | 60 | 200 |

| 50 | 10 | 30 | 55 | 180 |

| 64 | 10 | 30 | 50 | 160 |

| 3 Stage | ||||

| 100 | 7 | 20 | 45 | 110 |

| 120 | 7 | 20 | 40 | 100 |

| 160 | 7 | 20 | 40 | 90 |

| 200 | 7 | 20 | 35 | 85 |

| 256 | 7 | 20 | 30 | 75 |

| 512 | 5 | 15 | 25 | 60 |

| 1000 | 3 | 10 | 25 | 50 |

Additional Technical Specifications

| Item | Unit | Stage | Specification |

|---|---|---|---|

| Emergency stop torque | Nm | 1,2,3 | 3× rated output torque |

| Rated input speed | rpm | 1,2,3 | 3000–4500 |

| Maximum input speed | rpm | 1,2,3 | 6000 |

| Backlash (P1) | arcmin | 1 | ≤3 |

| 2 | ≤6 | ||

| 3 | ≤8 | ||

| Torsional rigidity | Nm/arcmin | – | Model dependent |

| Allowable radial force | N | 1,2,3 | Up to 3000 |

| Allowable axial force | N | 1,2,3 | Up to 2000 |

| Service life | hrs | – | ≥20,000 |

| Efficiency | % | 1 | 97% |

| 2 | 95% | ||

| 3 | 90% | ||

| Working temperature | °C | – | –10°C to +90°C |

| Protection grade | – | – | IP65 |

| Lubrication | – | – | Synthetic lubricating grease |

| Installation direction | – | – | Any direction |

| Noise level | dB | 1,2 | ≤52–58 |

| 3 | ≤65–68 |

Application

Automation & Industrial Machinery

- Packaging machines

- Assembly automation

- Linear actuators

Robotics & Motion Control

- Robotic arms

- Precision positioning systems

- Multi-axis servo platforms

CNC & Processing Equipment

- CNC cutting and milling machines

- Laser processing

- Indexing equipment

Electronics Manufacturing

- PCB handling

- Inspection systems

Medical & Laboratory Automation

Automated testing systems

Diagnostic equipment

FAQs

Yes. NUODUN’s core competitiveness lies in the synergistic advantage of “customization + system integration.” We support structural customization, torque customization, input flange customization, mounting interface customization, stroke customization and more for products such as planetary gearboxes, screw jacks, electric cylinders, and gearboxes. The typical lead time for standard non-standard customization is 7–20 days, while more complex engineered projects are usually delivered within 3–6 weeks.

Our engineering strength comes from long-term R&D investment, CAE simulation, lifetime calculation databases, modular design frameworks, and a mature testing/verification system. This ensures that every customized solution is not only manufacturable, but also reliable under real-world loads — balancing precision, durability, and cost efficiency.

Our products are widely used in photovoltaic manufacturing, semiconductor equipment, automotive production, metallurgy, logistics, medical devices, aerospace, stage automation, and industrial automation — especially where precision positioning, heavy loads, or long service life are required.

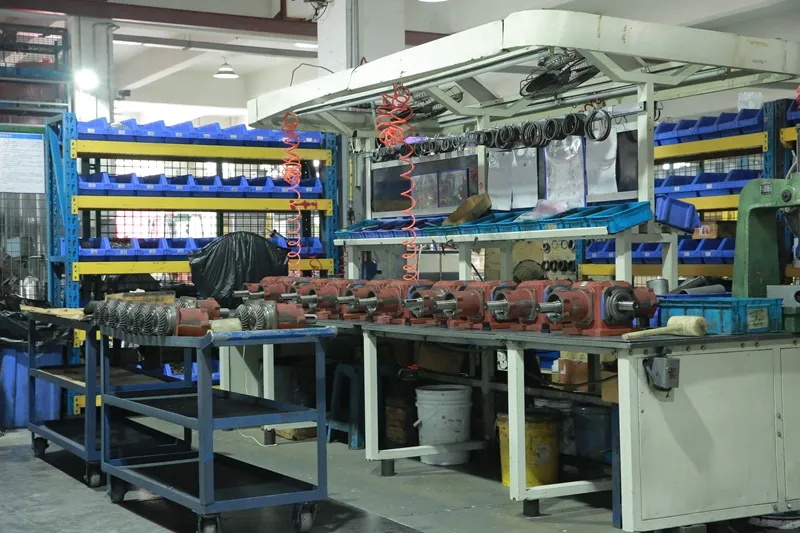

All products undergo type testing, torque testing, vibration testing, life testing, noise measurement, and precision inspection. Core components such as gears, screws, and bearings are produced using advanced machining, grinding, heat treatment, and automated assembly processes.

Yes. We offer remote technical support, installation guidance, troubleshooting, selection assistance, and long-term spare parts support for OEM/ODM partners.